API Manufacturing & Production is the backbone of the pharmaceutical industry, playing a crucial role in delivering safe and effective medicines to patients worldwide. Active Pharmaceutical Ingredients (APIs) are the core biologically active substances that produce the intended therapeutic effect in any drug formulation. Without high-quality APIs, medicines cannot meet safety, efficacy, and regulatory standards.

A well-structured API manufacturing process ensures consistent product quality, regulatory compliance, operational efficiency, and cost control. It involves carefully designed chemical or biological synthesis, strict monitoring of critical process parameters (CPP), adherence to critical quality attributes (CQA), impurity control, and validated production systems.

In this comprehensive guide, we will explore every major aspect of API Manufacturing & Production — from synthetic route design and fermentation-based APIs to batch and continuous manufacturing, scale-up studies, technology transfer, yield optimization, solvent recovery, and process robustness. This detailed overview will help you understand how pharmaceutical companies ensure quality, efficiency, and compliance at every stage of API production.

1. API Manufacturing Process

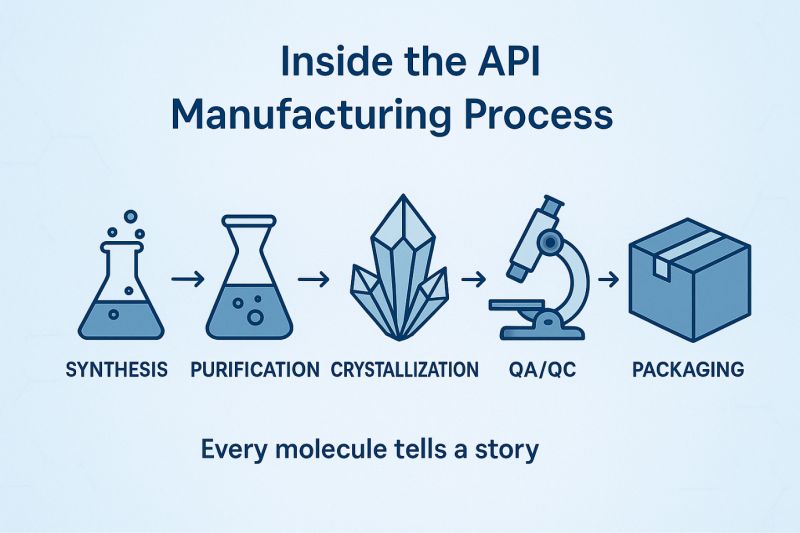

The API manufacturing process involves converting raw materials into a purified active compound. It typically includes:

Raw material selection

Reaction stages

Isolation and purification

Drying and milling

Final quality testing

Each step must comply with GMP (Good Manufacturing Practices) to maintain product quality and consistency. Proper documentation, validated equipment, and in-process controls are essential to ensure traceability and regulatory compliance. Manufacturers also perform risk assessments to minimize variability and prevent batch failures. A well-controlled API manufacturing process ensures consistent therapeutic performance in the final drug product.

2. Synthetic Route Design

Synthetic route design is the foundation of API Manufacturing & Production. It determines:

Number of reaction steps

Type of reagents and solvents

Yield efficiency

Cost-effectiveness

Environmental impact

An optimized synthetic route reduces impurities, improves yield, and simplifies scale-up. It also enhances safety by minimizing hazardous intermediates and controlling exothermic reactions. Efficient route design lowers production costs and shortens manufacturing timelines. Sustainable chemistry principles are increasingly applied to reduce waste and environmental burden.

3. Fermentation-Based API

Some APIs are produced using microbial fermentation. This is common for:

Antibiotics

Hormones

Vitamins

Enzymes

Fermentation-based API production involves:

Strain selection

Media optimization

Bioreactor control

Downstream purification

This method is widely used for biologically derived compounds. Strict control of temperature, pH, and oxygen levels is necessary to maximize productivity. Downstream processing plays a critical role in achieving high purity levels. Fermentation technology continues to evolve with advances in biotechnology and genetic engineering.

4. Semi-Synthetic API

Semi-synthetic APIs combine natural compounds with chemical modifications. This method:

Enhances potency

Improves stability

Reduces side effects

It is common in antibiotic and steroid manufacturing. Semi-synthesis allows manufacturers to improve pharmacological properties while maintaining biological effectiveness. This approach bridges the gap between purely natural and fully synthetic compounds. It also enables cost-effective large-scale production of complex molecules.

5. Process Flow Diagram (PFD)

A Process Flow Diagram (PFD) visually represents the API manufacturing process. It includes:

Distillation units

Filtration systems

Dryers

Solvent recovery units

PFDs help in process optimization and regulatory documentation. They provide a clear overview of material flow and equipment interaction. Engineers use PFDs to identify bottlenecks and improve operational efficiency. Regulatory authorities often review PFDs during audits and inspections.

6. Batch Manufacturing

Batch manufacturing produces API in fixed quantities. Key benefits:

Flexibility

Easier quality control

Suitable for small-scale production

However, it may involve longer production cycles. Each batch undergoes thorough testing before release, ensuring high compliance standards. Batch manufacturing is ideal for multi-product facilities. It also allows easier troubleshooting and process adjustments.

7. Continuous Manufacturing

Continuous manufacturing operates without interruption. Advantages include:

Higher efficiency

Reduced production time

Better process control

Lower operational costs

It is increasingly preferred in modern API Manufacturing & Production. Continuous systems allow real-time monitoring and automated adjustments. This approach reduces human error and improves consistency. Regulatory agencies are encouraging continuous manufacturing due to its reliability and scalability.

8. Scale-Up Studies

Scale-up studies transition production from laboratory to commercial scale. Critical considerations:

Heat transfer

Mixing efficiency

Reaction kinetics

Equipment compatibility

Improper scale-up can lead to reduced yield and impurity formation. Engineers conduct pilot trials to validate process performance at larger volumes. Scale-up requires careful evaluation of safety risks and reaction behavior. Successful scale-up ensures commercial feasibility without compromising quality.

9. Technology Transfer

Technology transfer ensures smooth movement of processes from R&D to manufacturing sites. It involves:

Documentation

Equipment matching

Training

Successful technology transfer minimizes production risks. Clear communication between development and production teams is essential. Proper transfer documentation ensures regulatory compliance and reproducibility. A well-managed technology transfer accelerates product commercialization.

10. Reprocessing & Rework

Reprocessing and rework correct batches that do not meet specifications. However:

Must comply with regulatory guidelines

Should not compromise API quality

Requires proper documentation

These activities are carefully evaluated through risk assessment procedures. Regulatory authorities require scientific justification before approval. Excessive rework can indicate process instability and must be addressed. Properly controlled reprocessing can reduce material loss and financial impact.

11. Yield Optimization

Yield optimization improves profitability in API Manufacturing & Production. Methods include:

Reaction condition optimization

Solvent selection

Catalyst improvement

Minimizing side reactions

Higher yield directly reduces manufacturing costs. Process analytical technologies (PAT) help monitor reaction performance in real time. Optimized yield improves raw material utilization and reduces waste generation. Continuous improvement strategies enhance long-term operational efficiency.

12. Critical Process Parameters (CPP)

Critical Process Parameters (CPP) are variables that impact API quality. Examples:

Temperature

Pressure

pH

Agitation speed

Reaction time

Strict monitoring of CPP ensures product consistency. Advanced control systems track parameter deviations instantly. Maintaining CPP within validated ranges prevents batch rejection. Effective CPP management supports regulatory compliance and product reliability.

13. Critical Quality Attributes (CQA)

Critical Quality Attributes (CQA) define product quality standards, including:

Purity

Potency

Particle size

Residual solvents

Polymorphic form

CQA must remain within acceptable limits to ensure drug safety. Analytical testing verifies that each batch meets established specifications. CQA assessment is based on risk management principles. Controlling CQA ensures consistent therapeutic performance.

14. Impurity Formation & Control

Impurities can arise from:

Side reactions

Raw material contamination

Degradation

Solvent residues

Effective impurity control strategies include:

Process optimization

In-process monitoring

Analytical testing (HPLC, GC)

Regulatory agencies strictly monitor impurity levels. Identification and qualification of impurities are essential for drug approval. Advanced analytical tools help detect trace-level contaminants. Proper impurity control safeguards patient safety.

15. Solvent Recovery

Solvent recovery reduces environmental impact and production costs. Techniques include:

Distillation

Condensation

Recycling systems

Efficient solvent recovery supports sustainable API Manufacturing & Production. Recovered solvents must meet purity specifications before reuse. This practice reduces hazardous waste generation. Sustainable manufacturing enhances corporate responsibility and regulatory compliance.

16. Mother Liquor Management

Mother liquor contains residual solvents and unreacted materials. Proper management:

Enhances material recovery

Reduces waste

Improves process efficiency

Recycling strategies can significantly improve profitability. Advanced separation techniques recover valuable intermediates. Effective management reduces environmental discharge. Optimized mother liquor handling supports sustainable manufacturing practices.

17. Process Robustness

Process robustness ensures consistent product quality despite minor variations in parameters. It is achieved through:

Risk assessment

Design of Experiments (DoE)

Process validation

Continuous monitoring

Robust processes reduce batch failures and regulatory risks. Statistical analysis helps identify variability sources. Continuous improvement strengthens manufacturing reliability. A robust process ensures long-term product consistency and market success.

Why API Manufacturing & Production Is Critical for Pharma Success

API Manufacturing & Production directly impacts:

Drug safety

Regulatory approval

Production cost

Market competitiveness

Companies that invest in optimized processes, quality control, and continuous improvement gain long-term advantages.

Conclusion

API Manufacturing & Production is a highly complex, science-driven process that forms the foundation of modern pharmaceuticals. From synthetic route design and fermentation-based production to scale-up studies, technology transfer, and process robustness, every stage plays a critical role in ensuring drug safety, quality, and regulatory compliance.

A well-optimized API manufacturing process focuses on controlling Critical Process Parameters (CPP), maintaining Critical Quality Attributes (CQA), minimizing impurity formation, and improving yield efficiency. Additionally, strategies such as solvent recovery, mother liquor management, and continuous manufacturing enhance sustainability and cost-effectiveness.

As regulatory expectations continue to evolve and global demand for high-quality medicines increases, companies that invest in innovation, process optimization, and quality-driven manufacturing systems will remain competitive. Ultimately, strong API Manufacturing & Production practices ensure the consistent delivery of safe, effective, and reliable medicines to patients worldwide.

Frequently Asked Questions (FAQ)

1. What is API Manufacturing & Production?

API Manufacturing & Production refers to the industrial process of producing active pharmaceutical ingredients used in medicines.

2. What is the difference between batch and continuous manufacturing?

Batch manufacturing produces fixed quantities, while continuous manufacturing runs nonstop with improved efficiency and consistency.

3. What are CPP and CQA in API manufacturing?

CPP (Critical Process Parameters) are process variables that impact quality, while CQA (Critical Quality Attributes) define the measurable properties that ensure product safety and efficacy.

4. Why is impurity control important?

Impurity control ensures drug safety, regulatory compliance, and patient protection.

5. What is scale-up in API Manufacturing & Production?

Scale-up is the transition from laboratory-scale production to commercial manufacturing while maintaining quality and yield.