Global regulatory authorities consistently highlight the importance of documentation and data integrity.

Key guidelines include:

Regulators evaluate Good documentation practices in pharma during inspections by reviewing:

Completeness of records

Data consistency and traceability

Corrections and error handling

Electronic system controls

Record retention and archiving

Why Documentation Is Critical in Pharma

Documentation serves multiple critical purposes:

Proof of compliance: Demonstrates adherence to GMP

Traceability: Tracks who did what, when, and why

Consistency: Ensures reproducible processes

Risk management: Helps identify deviations and trends

Legal evidence: Supports regulatory and legal requirements

Weak documentation undermines the entire quality system. That is why Good documentation practices in pharma are considered a foundational GMP requirement.

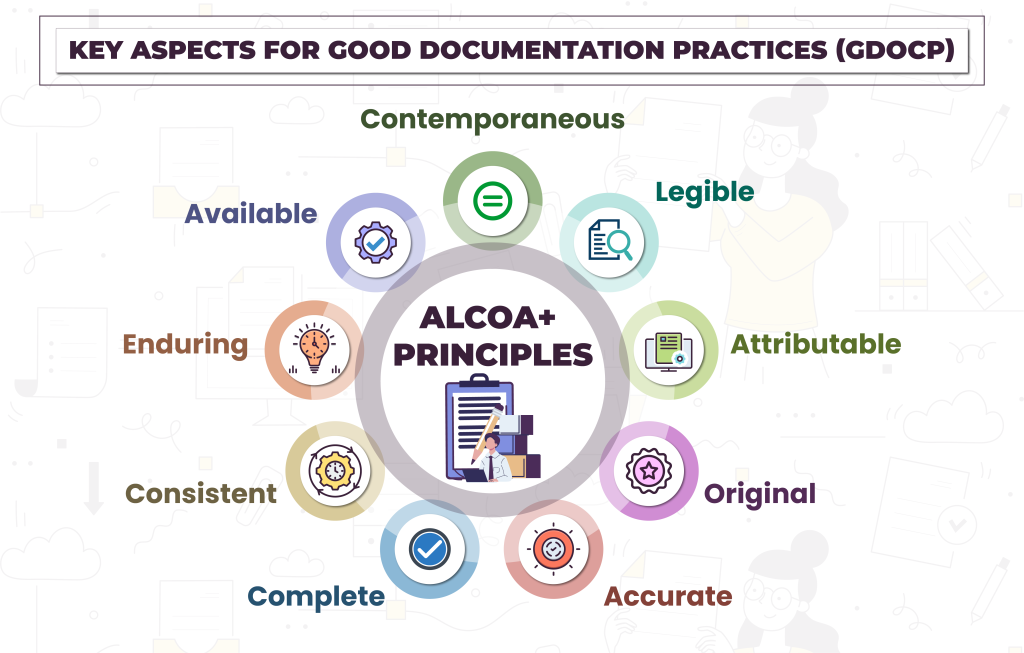

Understanding ALCOA and ALCOA+

ALCOA is a set of principles originally defined to ensure data integrity. Over time, regulators expanded it to ALCOA+ to address modern risks, especially electronic data management.

ALCOA Principles

Attributable

Legible

Contemporaneous

Original

Accurate

ALCOA+ Adds

Complete

Consistent

Enduring

Available

Together, ALCOA+ forms the backbone of Good documentation practices in pharma.

ALCOA+ Explained with Practical GMP Examples

1. Attributable

Every data entry must clearly identify who performed the activity and when.

GMP Example:

Non-compliance example:

Attributability ensures accountability and traceability under Good documentation practices in pharma.

2. Legible

Records must be readable, permanent, and understandable throughout their retention period.

GMP Example:

Non-compliance example:

Illegible data is treated as missing data during audits.

3. Contemporaneous

Data must be recorded at the time the activity is performed, not later.

GMP Example:

Non-compliance example:

Contemporaneous recording is a core expectation of Good documentation practices in pharma.

4. Original

Original records are the first capture of data or a verified true copy.

GMP Example:

Non-compliance example:

5. Accurate

Data must reflect the true value without manipulation or selective reporting.

GMP Example:

Accuracy is essential to maintain trust in Good documentation practices in pharma.

6. Complete

All data, including repeats, rejections, and deviations, must be included.

GMP Example:

Non-compliance example:

7. Consistent

Data should follow a logical sequence with consistent time stamps and formats.

GMP Example:

8. Enduring

Records must be preserved in durable media for the entire retention period.

GMP Example:

9. Available

Records must be readily retrievable for review or inspection.

GMP Example:

Availability is a key inspection focus in Good documentation practices in pharma.

Types of GMP Documents Covered Under GDP

Controlled Documents

SOPs

Policies

Protocols

Specifications

Uncontrolled / Operational Records

BMRs and BPRs

Equipment logbooks

Laboratory worksheets

Both categories must comply with Good documentation practices in pharma.

GDP Rules for Handwritten Entries

Key rules include:

Use permanent ink

No backdating

No correction fluid

Single-line strike-through for corrections

Initial, date, and reason for correction

Correct error handling is frequently reviewed during inspections.

Good Documentation Practices for Electronic Records

Electronic systems must comply with:

21 CFR Part 11

EU GMP Annex 11

Key controls include:

Unique user IDs

Role-based access

Audit trails

Data backups

Electronic compliance is now inseparable from Good documentation practices in pharma.

Common GDP Errors Observed in Audits

Regulators frequently cite:

Backdated entries

Missing signatures

Uncontrolled documents

Incomplete raw data

Poor archival practices

Most data integrity observations stem from GDP failures.

Best Practices to Strengthen GDP Compliance

Regular GDP training

Simple and clear SOPs

Periodic self-inspections

Use of templates and checklists

Digital QMS implementation

A strong GDP culture supports sustainable compliance.

Role of Training in GDP

Training ensures that personnel:

Training effectiveness directly impacts Good documentation practices in pharma.

GDP and Regulatory Inspections

During inspections, auditors assess:

Strong GDP practices reduce inspection risk and build regulatory confidence.

GDP as a Foundation of Quality Culture

Good documentation practices in pharma are not about paperwork—they reflect an organization’s quality mindset. When documentation is accurate, complete, and transparent, it builds trust with regulators and ensures patient safety.

Conclusion

Good documentation is the backbone of pharmaceutical quality systems. By applying ALCOA+ principles consistently, organizations can ensure data integrity, regulatory compliance, and operational excellence. Good documentation practices in pharma protect patients, support inspections, and enable continuous improvement in an increasingly regulated global environment.

FAQ: Good Documentation Practices in Pharma

1. What are Good documentation practices in pharma?

Good documentation practices in pharma are a set of GMP principles that ensure all pharmaceutical records are accurate, complete, traceable, and reliable. They confirm that activities were performed as approved and help maintain data integrity throughout the product lifecycle.

2. Why are Good documentation practices in pharma important?

Good documentation practices in pharma are critical because documentation serves as legal evidence of compliance. Poor documentation can lead to regulatory observations, warning letters, product recalls, and loss of market authorization.

3. What does ALCOA+ mean in GDP?

ALCOA+ represents data integrity principles used in Good documentation practices in pharma:

Attributable

Legible

Contemporaneous

Original

Accurate

Complete

Consistent

Enduring

Available

These principles ensure data reliability in both paper and electronic records.

4. Is ALCOA+ mandatory under GMP?

Yes. While ALCOA+ may not always be written word-for-word in regulations, global regulators expect compliance with these principles as part of Good documentation practices in pharma and data integrity requirements.

5. Which documents are covered under GDP?

GDP applies to all GMP-related documents, including SOPs, batch manufacturing records, analytical worksheets, logbooks, validation documents, calibration records, training records, and electronic data.

6. How should errors be corrected in GMP documents?

Errors must be corrected using a single-line strike-through, with the correct entry written nearby, along with initials, date, and reason if required. Correction fluid, overwriting, or backdating is not allowed under Good documentation practices in pharma.