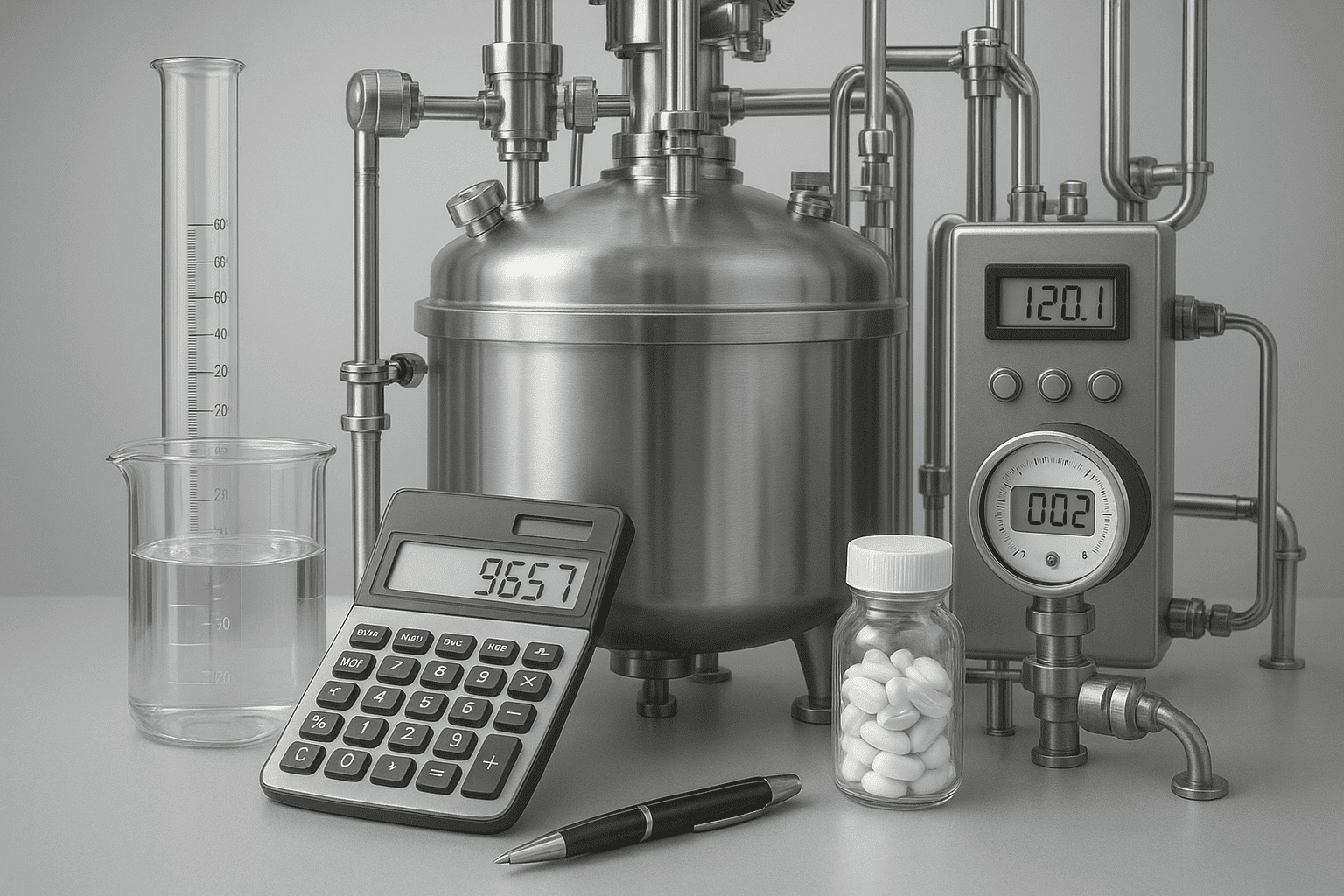

In the pharmaceutical industry, reactors are critical equipment that drive chemical reactions required for drug synthesis, formulation, and production. From small-scale R&D labs to large-scale manufacturing plants, reactors ensure controlled reactions under specific conditions like temperature, pressure, mixing, and pH.

Understanding reactor types, design principles, applications, and safety measures is essential for pharmaceutical engineers, researchers, and quality professionals. This guide covers all important topics related to reactor in pharmaceuticals.

1. What is a Reactor in Pharmaceuticals?

A pharmaceutical reactor is a vessel used to carry out chemical reactions under controlled conditions to produce active pharmaceutical and Pharmacalculations ingredients (APIs), intermediates, and excipients. Reactors also play a vital role in fermentation, crystallization, hydrolysis, polymerization, and neutralization processes.

Types of Reactors in Chemical Engineering

1. Batch Reactors

Operate with fixed quantities of reactants.

Ideal for small-scale production or processes requiring flexibility.

Commonly used in pharmaceuticals, fine chemicals, and specialty products.

2. Continuous Stirred Tank Reactors (CSTR)

Allow continuous input of reactants and removal of products.

Provide uniform mixing and steady-state operation.

Widely used in large-scale chemical manufacturing.

3. Plug Flow Reactors (PFR)

Reactants flow continuously through a tubular reactor.

No back-mixing, making it efficient for high conversion rates.

Common in petrochemical and polymer industries.

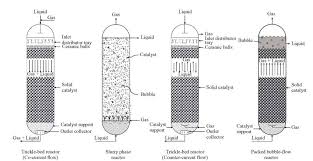

4. Packed Bed Reactors (PBR)

Contain catalysts packed inside a tube or column.

Promote heterogeneous catalytic reactions.

Extensively used in refining and gas-phase reactions.

5. Fluidized Bed Reactors

Catalyst particles are suspended in fluid, improving heat and mass transfer.

Applied in combustion, cracking, and gasification processes.

Read more: reactor in pharmaceuticals

Documents Related to Reactors

1. Technical Documents

P&ID (Piping and Instrumentation Diagram): Shows the piping, valves, sensors, and instrumentation connected to the reactor.

Process Flow Diagram (PFD): Outlines material flow, utilities, and reactor placement in the process.

Material Balance & Energy Balance Sheets: Essential for sizing and designing reactors.

Equipment Datasheets: Detailed specifications of the reactor (volume, pressure, material of construction, agitator type, etc.).

Design Calculation Sheets: Includes residence time, conversion, heat transfer, and kinetics.

2. Qualification & Validation Documents

DQ (Design Qualification): Verifies reactor design against user requirements.

IQ (Installation Qualification): Confirms proper installation of the reactor.

OQ (Operational Qualification): Ensures reactor operates as per defined parameters.

PQ (Performance Qualification): Demonstrates reactor performance under real process conditions.

3. Standard Operating Procedures (SOPs)

SOP for Reactor Charging: Guidelines for adding raw materials safely.

SOP for Reactor Operation: Instructions for temperature, pressure, agitation, and reaction control.

SOP for Reactor Cleaning: Steps for CIP (Clean-In-Place) or manual cleaning.

SOP for Maintenance & Calibration: Preventive maintenance schedules and calibration records.

4. Safety & Compliance Documents

HAZOP Study Report (Hazard and Operability): Risk assessment for reactor operation.

MSDS (Material Safety Data Sheets): Safety data for reactants and products handled in reactors.

Pressure Vessel Certifications: Legal compliance for pressure-rated reactors.

Environmental Impact Assessment (EIA): Emission and waste control related to reactor operation.

5. Research & Academic Documents

Reactor Design Notes: Covering kinetics, residence time distribution (RTD), and scale-up.

Case Studies: Examples of reactor performance in different industries.

Lab Experiment Reports: Data on small-scale reactor runs for process development.

White Papers / Journal Articles: Advanced research on reactor modeling and optimization.

Steps in Designing a Reactor

Designing a reactor is one of the most important tasks in chemical and pharmaceutical engineering. The design ensures that the reactor produces the desired product efficiently, safely, and economically.

Here are the main steps in reactor design:

1. Define the Process Requirements

Identify the chemical reaction(s) to be carried out.

Define desired products, by-products, and conversion level.

Specify operating conditions (temperature, pressure, catalysts, solvents).

Establish whether the process will be batch, semi-batch, or continuous.

2. Collect Reaction Kinetics & Thermodynamics Data

Obtain reaction rate laws, order, and rate constants.

Study equilibrium data, heat of reaction, and energy requirements.

Evaluate possible side reactions and reaction mechanisms.

3. Material and Energy Balance

Perform mass balance to determine reactant consumption and product formation.

Perform energy balance to calculate heat requirements, cooling/heating loads.

Decide on external utilities (steam, chilled water, etc.).

4. Select Reactor Type

Choose the best reactor type based on process needs:

Batch Reactor → flexible, small-scale.

CSTR (Continuous Stirred Tank Reactor) → good for uniform mixing.

PFR (Plug Flow Reactor) → efficient for large-scale continuous production.

Packed/Fluidized Bed Reactor → best for catalytic reactions.

5. Determine Reactor Size & Volume

Calculate residence time (τ) needed for required conversion.

Use kinetic equations to find reactor volume.

Factor in scaling from lab to pilot to industrial scale.

6. Heat Transfer & Mixing Considerations

Design appropriate agitation system (impeller type, speed).

Ensure proper heat transfer (jackets, coils, external heat exchangers).

Prevent hot spots or uneven temperature distribution.

7. Mechanical Design & Materials of Construction

Select material of construction (SS316, Hastelloy, Glass-Lined, etc.) based on corrosion resistance and safety.

Mechanical design must follow ASME / GMP / pressure vessel standards.

Include design for pressure, temperature, and stress analysis.

8. Safety & Control Systems

Incorporate pressure relief valves, rupture discs, safety interlocks.

Design for emergency shutdown procedures.

Implement process control systems (DCS/PLC/SCADA) for monitoring.

9. Cost Analysis & Feasibility

Estimate capital cost (CAPEX) and operating cost (OPEX).

Optimize reactor size and operation for minimum cost per kg of product.

Perform economic feasibility study.

10. Validation & Scale-Up

Test at lab scale → pilot plant → commercial scale.

Verify performance against design expectations.

Document qualification protocols (DQ, IQ, OQ, PQ).

Factors Affecting Reactor Design

Designing an efficient reactor requires careful consideration of:

Reaction kinetics (rate of reaction).

Thermodynamics (temperature and pressure effects).

Mixing and mass transfer.

Safety considerations (explosive or hazardous reactions).

Scale-up requirements from lab to industrial scale.

Applications of Reactors in Industries

Reactors are widely used across industries:

Pharmaceuticals – drug synthesis and fermentation.

Petrochemicals – cracking and polymerization.

Energy – biofuel production and nuclear reactors.

Food Processing – fermentation for beverages and additives.

Conclusion

Reactors in pharmaceuticals are the core of drug manufacturing processes, ensuring that chemical and biological reactions occur under controlled, safe, and efficient conditions. From batch reactors for flexible production to glass-lined reactors for solvent-based processes and bioreactors for biologics, each type serves a vital role in the industry.

A well-designed reactor improves product yield, quality, and compliance with GMP standards, while also reducing risks and operational costs. With advancements in continuous manufacturing, automation, and sustainable reactor technologies, the pharmaceutical industry is moving toward greater efficiency, safety, and innovation.

In short, reactors are not just equipment—they are the backbone of pharmaceutical production, driving the future of medicine.

FAQ

1. What are the main types of reactors in chemical engineering?

The common types include Batch Reactors, Continuous Stirred Tank Reactors (CSTR), Plug Flow Reactors (PFR), Packed Bed Reactors, and Fluidized Bed Reactors. The choice depends on the reaction type and production scale.

2. What factors influence reactor design?

Key factors are reaction kinetics, thermodynamics, material & energy balances, safety requirements, mixing, heat transfer, and cost considerations.

3. What is the difference between a Batch Reactor and a Continuous Reactor?

Batch Reactor: Reactants are charged, reaction occurs, and products are removed after completion (best for small-scale or flexible production).

Continuous Reactor: Reactants are fed continuously and products are withdrawn simultaneously (best for large-scale, steady production).

4. Why is heat transfer important in reactor design?

Heat transfer ensures that the reactor operates within the desired temperature range, preventing hot spots, thermal runaway, or incomplete reactions.

5. What is scale-up in reactor design?

Scale-up is the process of moving from lab-scale experiments → pilot plant → full industrial reactor while maintaining performance, safety, and efficiency.